Technology

We do not rely on everything being produced correctly!

For each produced Rebar Splice, the crimping result is checked by the CRIMPER software. If the required parameters of the respective crimping have not been reached, a warning is given to the operator and the machine interrupts the process.

In addition, the CRIMPER machine documents the processing of each individual ZENTOR® coupler per order and batch and thus offers documented security that deliveries to your customers also have the required quality

Performance

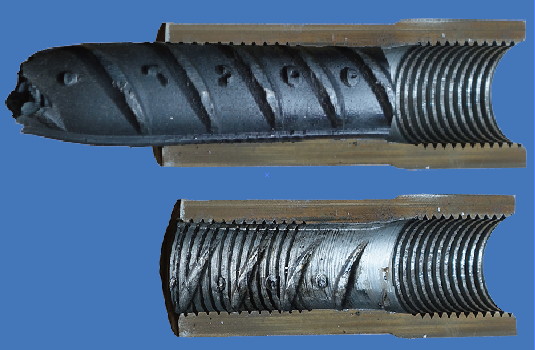

The crimping process does not reduce the cross-section of the rebar, this ensures that the maximum load-bearing capacity of the rebar is maintained.The CRIMPER has been optimized so that the pressing forces of the machine with a maximum pressing force of 2500 tons are evenly distributed and act constantly on the ZENTOR® coupler. This protects the rebar and locks itself optimally with the ZENTOR® coupler, creating a connection that is stronger than the rebar itself!

Quality

CRIMPER are manufactured under strict quality controls in an ISO9001 certified company and, of course, are only placed on the market with a CE-mark. Regular quality controls ensure permanent product quality by our team, also at the customer.