Quality & Safety

Switzerland is known for its quality products with the highest precision.

For the DUCA Systems Group, quality, precision & safety is not just a principle, but an elementary part of business processes.

It is precisely for this reason that we not only count well-known testing institutes in Europe among our partners, but also have our own in-house test laboratory at the Regensdorf / Zurich, with which our products are subject to regular self-monitoring and further development.

Testing machine tensile force

max. length for tensile tests

max. length for pressure tests

Test`s /Year

CRIMPER-Machines and ZENTOR®- Couplers are manufactured under strict quality controls and, of course, only brought into the market with a CE-mark.Regular quality controls ensure permanent product quality by our team.

In the manufacture of

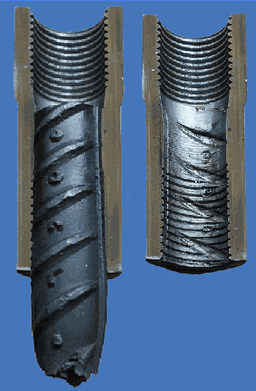

ZENTOR®-Rebar Splice does not reduce the cross-section of the rebar with the latest grouting technology! In this way, the rebar locks itself optimally with the coupler and it is ensured that the maximum load-bearing capacity of the rebar is maintained.

For every crimping with CRIMPER machines, the crimping result is checked by the CRIMPER Software. If the required range of the respective crimping has not been reached, a warning is issued to the operator. In addition, shows the recording of all pressing parameters of each ZENTOR®-Coupler the documented security for each order and batch, so that deliveries to your customers always have the required quality.